Products

- Spare Part

- Wire Cutting

- Wire Stripper

- Cable Stripping Laser

- Cut And Strip

- Crimp To Crimp

- Wire Crimper

- Bench Top

- Wire Crimping Applicators

- Wire Crimper - Ferrule

- Wire Stripping Crimping - Ferrule

- Wire Twister

- Marking Systems

- Cable Marking Laser

- Wire Feeding

- Wire Deposit

- Taping

- Cable Harness Production Panels

- Test Systems

- Ultrasonic Welding Systems

- Heat Shrinking

- Professional Hand Tools

- Accessories

- Direnç Kaynağı

Article number: 0312930

Komax İms 295 Marking Systems

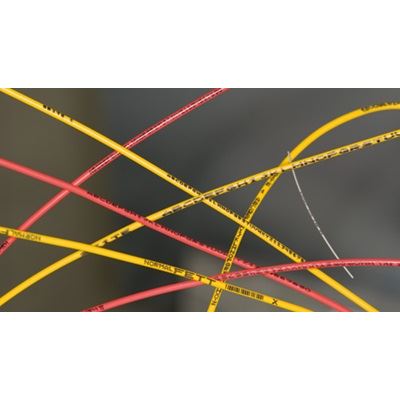

Ink-Jet markerScope of application

Inkjet MarkingThe latest generation of automatic wire processing machines features extreme flexibility and processes at high speeds. These operating conditions put tough requirements on wire marking that can only be met with appropriate solutions. Is the object to mark quicker, smaller, more reliably, with greater resistance or merely more cheaply? Komax has a range of marking systems that ensures the optimum solution for your specific application.

The Komax ims 295 BC (Black Colour), ims 295 BS (Black Small) and ims 295 MC (Multi Colour) inkjet marking systems excel in their high marking speeds and in the simple and reliable way in which they process the wire. All IMS marking systems have two different interfaces, an RS232 and an Ethernet (TCP/IP). That means they can be operated with current as well as future Komax machines. They are particularly suitable in combination with automatic Kappa strippers and with the Alpha, Gamma and Zeta fully automatic crimping machines.

Text input, setup parameters and all other settings for the marking text are easy to enter from the user interface of the basic machine. The number of marking texts is defined in ten initial markings, ten end markings and one continuous middle marking. The standard functions include bold, symbols, adjustable font width and height, double character spacing, inverse font, continuously alternating text and sample marking.

Ink density is measured constantly with the automatic solvent metering unit to ensure operation that is both ecological and economical. A condenser unit is available as an option to recover solvent. It reduces solvent consumption and virtually eliminates the presence of solvent from the air in the room.

The ink and solvent tanks are quick and easy to access. Inks can be replenished while marking is going on. With the ingenious control concept, top quality marking is achieved even when the wire is subject to high rates of acceleration or deceleration. In addition, a speed optimisation feature ensures that wire sections without marking are processed at the maximum possible wire processing speed.

The ims 295 inkjet marking systems can also be operated offline without the basic machine for simple applications. The marking settings are entered from the integrated membrane keyboard with VGA display.

To optimise marking quality, contrast and adherence, Komax has an extremely broad range of ink types on offer to match the line-up of Komax markers. Elaborate wire preparations are no longer required in most cases.

- Individual solutions to cover the widest variety of marking requirements

- Fully integrated in the Komax basic machines

- High marking speeds

- You can enter text input and settings conveniently from the GUI

- Simple to operate

- Easy to service

Technical data ims 295 BC

The ims 295 BC inkjet marking system is a fully integrated marker for black dye inks or lightly pig-mented inks. Pressure is built up automatically with a gear pump, thus eliminating the compressed air connection.

| ims 295 BC | |

|---|---|

| Integration in Komax machine | TopWin/KappaWin |

| Interface connection | RS232/Ethernet TCP/IP |

| Maximum of marking speed | 8m/s* (315in./s)* |

| Number of marking heads | 1 marking head 84kHz/60µm |

| Minimum font height | 1.0mm (0.04in.) |

| Maximum font height | 4.5mm (0.18in.) |

| Minimum wire diameter | 1.2mm (0.047in.) |

| Minimum wire cross section | approx. 0.35mm² |

| Tank volume ink/solvent | 1.25Liter (0.33gal.) |

| Inks | Non/lightly pigmented |

| Supply hose, length | 3m (118in.) |

| Ambient temperature | +5 bis +40°C** (41–104°F)** |

| Maximum relative humidity | 90%, non condensing |

| Power supply | 115/230V 50/60Hz |

| Compressed air supply | - |

| Dimensions (W×H×D) | 418×630×325mm (16.5×24.8×12.8in.) |

| Weight (net) | Approx. 26kg (57lb) |

* Cable specific (Unmarked sections of wire are automatically detected and processed at maximum speed)

** Depends on the ink used

Technical data ims 295 MC

This marking system was developed especially for marking with heavily pigmented inks. These inks are used for high-contrast and colour mark-ing. They adhere superbly to a wide variety of materials. The integrated ink circulation and mixing system (dispersant) ensures reliable processing in connection with heavily pigmented inks.

Komax goes so far with the ergonomic design that even the hydraulic system is neatly separated from the electronic components.

| ims 295 MC | |

|---|---|

| Integration in Komax machine | TopWin/KappaWin |

| Interface connection | RS232/Ethernet TCP/IP |

| Maximum of marking speed | 8m/s* (315in./s)* |

| Number of marking heads | 1 marking head 84kHz/60µm |

| Minimum font height | 1.0mm (0.04in.) |

| Maximum font height | 4.5mm (0.18in.) |

| Minimum wire diameter | 1.2mm (0.047in.) |

| Minimum wire cross section | approx. 0.35mm² |

| Tank volume ink/solvent | 1.25Liter (0.33gal.) |

| Inks | Heavily pigmented |

| Supply hose, length | 3m (118in.) |

| Ambient temperature | +5 bis +40°C** (41–104°F)** |

| Maximum relative humidity | 90%, non condensing |

| Power supply | 115/230V 50/60Hz |

| Compressed air supply | 6bar (87psi), filtered |

| Dimensions (W×H×D) | 418×630×325mm (16.5×24.8×12.8in.) |

| Weight (net) | Approx. 30kg (66lb) |

* Cable specific (Unmarked sections of wire are automatically detected and processed at maximum speed)

** Depends on the ink used

Technical data ims 295 BS

The ims 295 BS was specially developed for marking using small fonts and black ink.The marker is fitted with a 120kHz/40µm marking head, so it delivers compelling sharpness of detail to a minimum font height of 0.8mm (0.031in.).

The increased frequency and the smaller jet diameter make this model the fastest and most economical marker in the Komax ims series.

| ims 295 BS | |

|---|---|

| Integration in Komax machine | TopWin/KappaWin |

| Interface connection | RS232/Ethernet TCP/IP |

| Maximum of marking speed | 9m/s* (354in./s)* |

| Number of marking heads | 1 marking head 120kHz/40µm |

| Minimum font height | 0.8mm (0.031in.) |

| Maximum font height | 4.4mm (0.17in.) |

| Minimum wire diameter | 1.0mm (0.039in.) |

| Minimum wire cross section | approx. 0.13mm² |

| Tank volume ink/solvent | 1.25Liter (0.33gal.) |

| Inks | Non pigmented |

| Supply hose, length | 3m (118in.) |

| Ambient temperature | +5 bis +40°C** (41–104°F)** |

| Maximum relative humidity | 90%, non condensing |

| Power supply | 115/230V 50/60Hz |

| Compressed air supply | 6bar (87psi), filtered |

| Dimensions (W×H×D) | 418×630×325mm (16.5×24.8×12.8in.) |

| Weight (net) | Approx. 30kg (66lb) |

* Cable specific (Unmarked sections of wire are automatically detected and processed at maximum speed)

** Depends on the ink used

| Inkjet Marking |

|